I plan on re-adjusting my valves this week, I have flat tappet hydraulic lifters. Is this still the best method below?

Valve Adjustment Procedure

1. Valves can be set on a hot or cold engine. A cold engine is a lot more comfortable to work on. Major camshaft manufacturers recommend setting valves cold, to avoid erroneous adjustments on lifters that may be "pumped up" If you are setting valves on a fresh engine that has not been run, everything should be well lubricated before you begin.

2. Remove both valve covers and remove the spark plugs to make the engine easier to turn over. Also, If you are setting valves on all cylinders, it is generally easier and less confusing to just loosen all of the rocker arm adjustment nuts before you begin. This also allows for all of the internal lifter plungers to return to their "home" position.

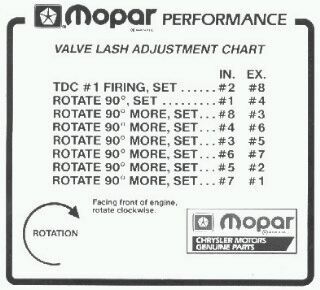

3. Using a long handled ratchet or breaker bar attached to the crank bolt, turn the engine over in the clockwise direction.

2. Remove both valve covers and remove the spark plugs to make the engine easier to turn over. Also, If you are setting valves on all cylinders, it is generally easier and less confusing to just loosen all of the rocker arm adjustment nuts before you begin. This also allows for all of the internal lifter plungers to return to their "home" position.

3. Using a long handled ratchet or breaker bar attached to the crank bolt, turn the engine over in the clockwise direction.

A. Starting with #1 cylinder, turn the engine over until the exhaust pushrod just begins to move up.

B. At this point, stop and adjust the intake valve on the same cylinder.

B. At this point, stop and adjust the intake valve on the same cylinder.

1) Tighten the rocker until you can roll the pushrod between your thumb and forefinger with the slightest bit of resistance.

2) At this point tighten between an additional quarter to half of a turn.

2) At this point tighten between an additional quarter to half of a turn.

C. You have now adjusted the #1 intake valve. You will now want to turn the engine over while watching the same intake pushrod that you just set, it will go full open and then begin to close. When it is almost closed, stop and adjust the exhaust rocker arm on that particular cylinder. By following this procedure, you are assured that both of the lifters are at the base circle of the cam and that there is no additional pre-load applied to them from cam lift at this point.

D. You are now able to repeat this procedure on the remaining cylinders.

D. You are now able to repeat this procedure on the remaining cylinders.

4.Re-install your valve covers and your valve adjustment procedure is finished