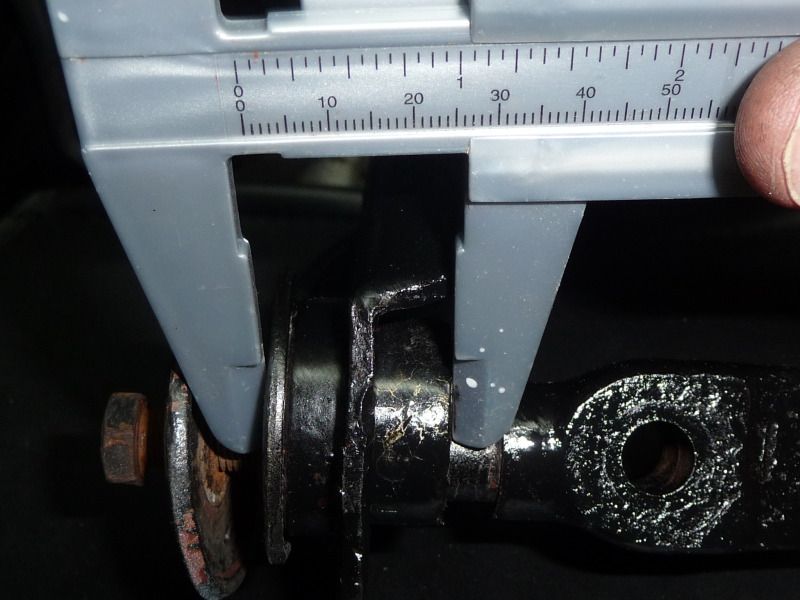

I've got my front end apart doing the disc brake swap and I can see why my poly bushings have been squeaking and riding so harshly. There is no lube left in them. I could barely move the control arms by hand until I loosened the bolts.

I am thinking about experimenting with tapping the shells for grease fittings.

I can't see why they wouldn't have had fittings in the first place. Cost, maybe.

Anybody try this? Good idea, bad idea? I need compatible grease for poly right?

Thanks,

Tom

I am thinking about experimenting with tapping the shells for grease fittings.

I can't see why they wouldn't have had fittings in the first place. Cost, maybe.

Anybody try this? Good idea, bad idea? I need compatible grease for poly right?

Thanks,

Tom