any body know just what the hp limits on a350 2 bolt block may be i think chevy built the 65 327 with 375 hp...i think that was the most powerful small block chevy put out.......ty tyvm

longhorn

1 - 18 of 18 Posts

we raced dirt tracks for years and many guys used 2 bolt 350`s at 375 to 450 hp

thanks t/a then i should be safe at 300/350 hp with a 2 bolt on the street

Joined

·

477 Posts

Like wyoming T/A said 400+ motors are not a problem. You will be fine with your goal.

Steve

Steve

Joined

·

537 Posts

I like to keep my 2-bolt 350 block limit to about 400 HP. I always use ARP main studs on the 2-bolt blocks for added security.

it seems like I have read here that the 400 sb 2 bolt is good to about 500 before you have to splay the caps... am I mistaken on that?

u want to run high HP/Revs (on any engine)

get tolerances even and right on spec Mains, big ends rings etc

Rods pistons, crank all balanced

Crank balance with everything including flywheel, harmonic balancer, torque converter, what ever is bolted to it.

line bored.

I do it even on and engine thats going to be granny footed and needs to last the next 20 or 30 yrs.

Basically Im lazy, and work hard at it...do it right and dont have to do it again or fix.

get tolerances even and right on spec Mains, big ends rings etc

Rods pistons, crank all balanced

Crank balance with everything including flywheel, harmonic balancer, torque converter, what ever is bolted to it.

line bored.

I do it even on and engine thats going to be granny footed and needs to last the next 20 or 30 yrs.

Basically Im lazy, and work hard at it...do it right and dont have to do it again or fix.

Joined

·

938 Posts

I Know in the chevy catolog that the 350 4 bolt is rated at 350 horse and add 2482 caps to the same block and its now rated at 450 horse and I don't believe they rate the 2 bolt blocks more the the 4 bolt blocks.

And on the 327 blocks using the smaller mains there is more cap due to the smaller bore making the caps stronger and your talking a 3.250 stroke VS 3.480 stroke big differance.

And a 400 and 454 blocks with 2 bolt caps is better as the caps are alot wider and have more register and helps keep the caps from walking and flexing.

And we get a lot of emails a calls about this subject and we are basing are info on more then just a couple of engines.

Check this link out

http://www.chevelles.com/forums/showthread.php?t=38173

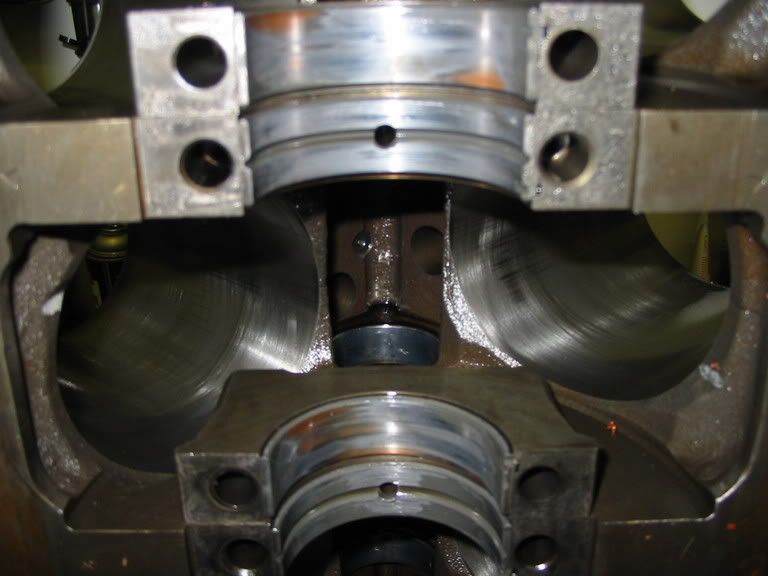

Here is a pic of a block that came to our shop for splayed caps as this was in a circle track car around 400 horse and this did have studs installed and from what I observed there was no signs of detonation as the pistons had no dicoloration on the underside and the head gaskets looked fine.

And over 31 years of doing this we have seen this many times on some street 383 engines as they were taken apart due to low oil pressure due to the bearings looking like the ones in the pic.

Notice the cap registers are distroyed

![Image]()

And on the 327 blocks using the smaller mains there is more cap due to the smaller bore making the caps stronger and your talking a 3.250 stroke VS 3.480 stroke big differance.

And a 400 and 454 blocks with 2 bolt caps is better as the caps are alot wider and have more register and helps keep the caps from walking and flexing.

And we get a lot of emails a calls about this subject and we are basing are info on more then just a couple of engines.

Check this link out

http://www.chevelles.com/forums/showthread.php?t=38173

Here is a pic of a block that came to our shop for splayed caps as this was in a circle track car around 400 horse and this did have studs installed and from what I observed there was no signs of detonation as the pistons had no dicoloration on the underside and the head gaskets looked fine.

And over 31 years of doing this we have seen this many times on some street 383 engines as they were taken apart due to low oil pressure due to the bearings looking like the ones in the pic.

Notice the cap registers are distroyed

I plan on rebuilding my 350 at the end of the summer. Horsepower should be a little over 400 and the cam I plan on using makes power to 6200rpm. I don't know if I have a 2 bolt or 4 bolt yet, but if its a 2 bolt I want to convert it to a 4 bolt. How much does it cost to convert to a 4 bolt? What if I wanted to splay the bolts, how much more does that cost? I know splayed caps are more than I need, but I over build everything so I only have to do it once.

I ran a 350 2 bolt main block with 11.1 compresssion with Nitrous on the street for over three years and never had a problem.

Joined

·

477 Posts

There are many 2 bolt engines running 400hp and slightly over just fine. Of course there are many things that determine how long this will last. Some factory 350 blocks are just plain better blocks (less core shift, better metal, thicker metal, etc.). Also a well balanced rotating assembly is a must. I mean the entire rotating assembly including dampener and flexplate/flywheel must be included when balancing. Another thing to keep in consideration is the RPM limits you will need to keep them around 6000. Of course the more insurance (studs, extra machine work to true the block up, etc etc.) you can add the better your chances are for a long life.

Steve

Steve

Joined

·

938 Posts

We machine alot of blocks for splayed caps and it cost alot of money to do it right and use good caps and for what it would cost I am sure you could find a good 4 bolt block maybe one with 2482 on the center caps as those are the nodular iron performance caps gm used on there performance engines.DenRS said:I plan on rebuilding my 350 at the end of the summer. Horsepower should be a little over 400 and the cam I plan on using makes power to 6200rpm. I don't know if I have a 2 bolt or 4 bolt yet, but if its a 2 bolt I want to convert it to a 4 bolt. How much does it cost to convert to a 4 bolt? What if I wanted to splay the bolts, how much more does that cost? I know splayed caps are more than I need, but I over build everything so I only have to do it once.

We base our info on more then just one engine as we build performance engines for a living and if we are going to spend the time to build a engine that makes over 400 horse I don't think we would start with 2 bolt block as we have a pretty good rep as for as building high performance engines and machining blocks for other shops and engine builders all over the country and so far no complaints and we deal witha lot of other performance shops and they think the same way as I do.

A engine over 400 horse using a good 4 bolt block is MUCH more dependable then a 2 bolt block as we have seen may 2 bolt blocks used where a 4 bolt should have been used.

Next time I talk GM I will see if I can talk to an engineer on how much power a 2 bolt block is good for but I already know there are some people here that know more then the engineers at GM as GM has done more testing the all us put together. LOL

thank u kurt ..that really tells me something..il be ok with mine @ 300 hp then dont plain ever to drag race just cruiseKURT said:I ran a 350 2 bolt main block with 11.1 compresssion with Nitrous on the street for over three years and never had a problem.

thanks cnc i never thought of that ..the stroke and smaller journal .....CNC BLOCKS N/E said:I Know in the chevy catolog that the 350 4 bolt is rated at 350 horse and add 2482 caps to the same block and its now rated at 450 horse and I don't believe they rate the 2 bolt blocks more the the 4 bolt blocks.

And on the 327 blocks using the smaller mains there is more cap due to the smaller bore making the caps stronger and your talking a 3.250 stroke VS 3.480 stroke big differance.

And a 400 and 454 blocks with 2 bolt caps is better as the caps are alot wider and have more register and helps keep the caps from walking and flexing.

And we get a lot of emails a calls about this subject and we are basing are info on more then just a couple of engines.

Check this link out

http://www.chevelles.com/forums/showthread.php?t=38173

Here is a pic of a block that came to our shop for splayed caps as this was in a circle track car around 400 horse and this did have studs installed and from what I observed there was no signs of detonation as the pistons had no dicoloration on the underside and the head gaskets looked fine.

And over 31 years of doing this we have seen this many times on some street 383 engines as they were taken apart due to low oil pressure due to the bearings looking like the ones in the pic.

Notice the cap registers are distroyed

![Image]()

Joined

·

2,519 Posts

My machine shop (GreenFlagRacing) said est: 2 bolt blocks 500hp and 4bolt 550hp. I have a 2 bolt, see what it runs in my sig.

Joined

·

938 Posts

We deal with some high end engines shops across the country and I know that they would not use a 2 bolt in a 500 horse application unless it had splayed caps. Hell the one in the pick was justo over 400 horse and that made a mess out of everything.speedfreek said:My machine shop (GreenFlagRacing) said est: 2 bolt blocks 500hp and 4bolt 550hp. I have a 2 bolt, see what it runs in my sig.

How dependable is a 2 bolt cap block at 500 horse as we have seen many times what happens to 2 bolts over 350 horse but we do this every day for a living and we get a lot of call and emails about this subject.

To build a 500 horse engine takes alot of money and good parts and I can't believe someone would start with a 2 bolt mains. If one of my customers came in a wanted a 500 to 550 horse engine and I told them a 2 bolt mains would be fine I am sure they would take there bussiness some where else. I would be scared to put something like that on the dyno.

500 horse on a 2 bolt block the guys in the shop will get good laugh out this one.

Joined

·

2,519 Posts

I'm pretty sure I have well over 400hp and mine is a 2 bolt with stock main bolts, stock crank and rods turning 7500rpm.CNC BLOCKS N/E said:We deal with some high end engines shops across the country and I know that they would not use a 2 bolt in a 500 horse application unless it had splayed caps. Hell the one in the pick was justo over 400 horse and that made a mess out of everything.

How dependable is a 2 bolt cap block at 500 horse as we have seen many times what happens to 2 bolts over 350 horse but we do this every day for a living and we get a lot of call and emails about this subject.

To build a 500 horse engine takes alot of money and good parts and I can't believe someone would start with a 2 bolt mains. If one of my customers came in a wanted a 500 to 550 horse engine and I told them a 2 bolt mains would be fine I am sure they would take there bussiness some where else. I would be scared to put something like that on the dyno.

500 horse on a 2 bolt block the guys in the shop will get good laugh out this one.

Joined

·

22,190 Posts

One thing worth remembering is how the engine is used plays a big part in how fast it wears out. Just because an engine is capable of 400 or 500 horsepower doesn't mean it's doing it all the time, or even much of the time.

The pics Carl posted are from a circle track race engine, probably a short track car. We're talking (1/4 mile track) about an engine that goes to WOT and pulls from 4500 rpm to 6500+, twice every 17 seconds, for 10-30 minutes at a time, 4-6 times per Friday night!

To see the equivalent wear in a (every weekend bracket race) drag race engine would take 5 years! (I didn't actually do the math, don't flame me if I'm off a decade or 2)

My street 383 will probably see the equivalent of one 10 lap qualifier in an ENTIRE SUMMER! A circle track car will probably run 2 or 3 10 lap races @ 20 WOT pulls each, plus either a semi or a main at 25 or 50 laps (50 or 100 WOT pulls) EVERY SINGLE FIRDAY NIGHT!

It makes good sense to build an engine strong enough to run WOT full power continuously, but very very very few engines are ever called on to actually prove they can do that.

The pics Carl posted are from a circle track race engine, probably a short track car. We're talking (1/4 mile track) about an engine that goes to WOT and pulls from 4500 rpm to 6500+, twice every 17 seconds, for 10-30 minutes at a time, 4-6 times per Friday night!

To see the equivalent wear in a (every weekend bracket race) drag race engine would take 5 years! (I didn't actually do the math, don't flame me if I'm off a decade or 2)

My street 383 will probably see the equivalent of one 10 lap qualifier in an ENTIRE SUMMER! A circle track car will probably run 2 or 3 10 lap races @ 20 WOT pulls each, plus either a semi or a main at 25 or 50 laps (50 or 100 WOT pulls) EVERY SINGLE FIRDAY NIGHT!

It makes good sense to build an engine strong enough to run WOT full power continuously, but very very very few engines are ever called on to actually prove they can do that.

1 - 18 of 18 Posts

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

- posts

- 2.4M

- members

- 90K

- Since

- 1998

A forum community dedicated to 1st generation Chevy Camaros owners and enthusiasts. Come join the discussion about performance, builds, restoration, modifications, classifieds, troubleshooting, reviews, and more!

Explore Our Forums