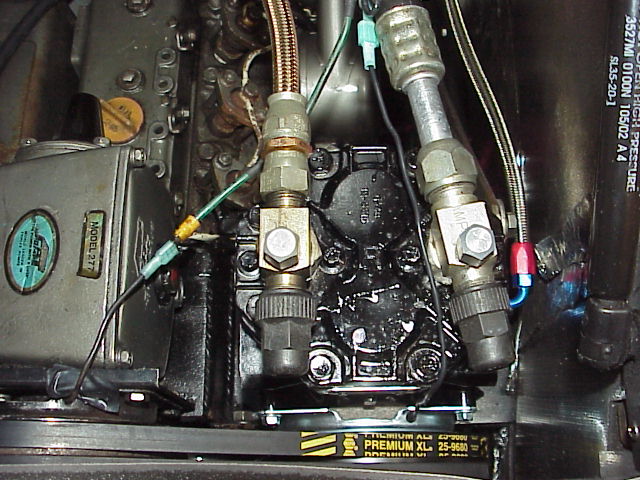

How much clearance is need between the steel piece that holds the cowl seal and the hood? I just installed the seal and the hood closes good. I looked from underneath and everything is sealing against the hood. Here are some pictures. I will shoot a bunch more tomorrow of all the goodies. Let me know what you think of the efi install so far. Thanks

Let me know what you think of the efi install so far. Thanks

Dougs72Nova

Update on Mass-Flo efi install and cowl air cleaner.

Dougs72Nova

Discussion starter

2,368 posts

·

Joined 2006

- Add to quote Only show this user

How much clearance is need between the steel piece that holds the cowl seal and the hood? I just installed the seal and the hood closes good. I looked from underneath and everything is sealing against the hood. Here are some pictures. I will shoot a bunch more tomorrow of all the goodies. Let me know what you think of the efi install so far. Thanks

Let me know what you think of the efi install so far. Thanks

Attachments

-

104.5 KB Views: 361

-

103.3 KB Views: 275

-

114 KB Views: 275

3,399 posts

·

Joined 2008

Re: Clearance for cowl air cleaner? Also, update on efi install.

Looking good, how long till you get it running

Looking good, how long till you get it running

Dougs72Nova

Discussion starter

2,368 posts

·

Joined 2006

Re: Clearance for cowl air cleaner? Also, update on efi install.

Thanks John. I have some other things going on right now, so probably in the next couple weeks. I have to install the new fuel tank and run all the braided lines and install the wire harness.Looking good, how long till you get it running

Thanks Patrick.:thumbsup:Spotless! And looking great.

Thanks Jeff.:thumbsup:Looks great Doug:thumbsup:

2,519 posts

·

Joined 2005

Re: Clearance for cowl air cleaner? Also, update on efi install.

Spotless! And looking great.

Spotless! And looking great.

1,383 posts

·

Joined 2002

Re: Clearance for cowl air cleaner? Also, update on efi install.

Looks great Doug:thumbsup:

Looks great Doug:thumbsup:

1,411 posts

·

Joined 2006

Re: Clearance for cowl air cleaner? Also, update on efi install.

You're air cleaner seal is on inside out.

You're air cleaner seal is on inside out.

Dougs72Nova

Discussion starter

2,368 posts

·

Joined 2006

Re: Clearance for cowl air cleaner? Also, update on efi install.

I turned it inside out and installed it. I thought that is how you did it. I remember a thread that clearly said to turn it inside out and then install it. It's a gm seal part#3955231.You're air cleaner seal is on inside out.

14,879 posts

·

Joined 2000

Re: Clearance for cowl air cleaner? Also, update on efi install.

looks great Doug, very clean. :thumbsup:

Jody

looks great Doug, very clean. :thumbsup:

Jody

Dougs72Nova

Discussion starter

2,368 posts

·

Joined 2006

Re: Clearance for cowl air cleaner? Also, update on efi install.

Thanks Jody!:thumbsup: Dave is telling my seal is on wrong. It's the only way the lip will go on the flange correctly. I turned the seal 180 degrees and then installed it. I think Dave is wrong on this one. Can you tell if it's correct? Thanks

looks great Doug, very clean. :thumbsup:

Jody

Thanks Jody!:thumbsup: Dave is telling my seal is on wrong. It's the only way the lip will go on the flange correctly. I turned the seal 180 degrees and then installed it. I think Dave is wrong on this one. Can you tell if it's correct? Thanks

3,560 posts

·

Joined 1999

Re: Clearance for cowl air cleaner? Also, update on efi install.

It looks like itis on right but some of them don't flare out like they should. Take the whole flange off and tape the seal back and then lay it face down with some kind of weight on it and let it set. Sort of smashing it flat and trying to train it.

It looks like itis on right but some of them don't flare out like they should. Take the whole flange off and tape the seal back and then lay it face down with some kind of weight on it and let it set. Sort of smashing it flat and trying to train it.

Dougs72Nova

Discussion starter

2,368 posts

·

Joined 2006

Re: Clearance for cowl air cleaner? Also, update on efi install.

Thanks Charley. There is only one way the seal will go on the flange correctly. If it's turned the wrong way the seal lip will be on the wrong side. Thanks again.

It looks like itis on right but some of them don't flare out like they should. Take the whole flange off and tape the seal back and then lay it face down with some kind of weight on it and let it set. Sort of smashing it flat and trying to train it.

Thanks Charley. There is only one way the seal will go on the flange correctly. If it's turned the wrong way the seal lip will be on the wrong side. Thanks again.

14,879 posts

·

Joined 2000

Re: Clearance for cowl air cleaner? Also, update on efi install.

Doug, I e-mailed Charley for the answer. Thanks Chuck!

Jody

Doug, I e-mailed Charley for the answer. Thanks Chuck!

Jody

Dougs72Nova

Discussion starter

2,368 posts

·

Joined 2006

Re: Clearance for cowl air cleaner? Also, update on efi install.

Thanks Jody.

Doug, I e-mailed Charley for the answer. Thanks Chuck!

Jody

Thanks Jody.

Dougs72Nova

Discussion starter

2,368 posts

·

Joined 2006

Re: Clearance for cowl air cleaner? Also, update on efi install.

Took your advice Charley.:yes:

Took your advice Charley.:yes:

Attachments

-

112.8 KB Views: 172

Dougs72Nova

Discussion starter

2,368 posts

·

Joined 2006

Thanks Mike.:thumbsup:

Thanks Andy.:thumbsup:Very clean looking setup Doug!!! Nice work.:thumbsup:

8,373 posts

·

Joined 2006

Question Doug; Will Mass Flo weld up a fuel rail on an original Torquer II? Anyone know? I've gone with Retrotek but am open to change.

See how the 'TB' is twisted?

![Image]()

Hope your seal comes out like this;

![Image]()

See how the 'TB' is twisted?

Hope your seal comes out like this;

14,879 posts

·

Joined 2000

Talk to Rob at Force Fuel Injection He does a ton of conversions.Question Doug; Will Mass Flo weld up a fuel rail on an original Torquer II? Anyone know? I've gone with Retrotek but am open to change.

See how the 'TB' is twisted?

Jody

8,373 posts

·

Joined 2006

Thanks for the options Jody and Doug.

And Doug, get a load of this.

Last year during the third week of March I fired up the system. Holy $hit! I runs good! The phone rings. It's a buddy who's keeping track of the system installation. I fill him in. He asks 'when is the next race?'. I check. FOUR HOURS! OMG! On go the race tires and the rest of my junk for the strip and off I go. Pay my money, pull to the line and go. BRAND NEW untested fuel system. Banged out an 11:89! First try. Fastest ever. Cold as hell, still winter. Then the computer started taking power out of it. Lost .2 on the next run. I could feel it take power when I hit second gear. The system was still a total mystery to me and I've not been able to match that run all last season. Weird huh? But that new roller cam is looking better every minute. But first on the list is my new air conditioned, enclosed (of course) car hauler. Real men come to the track with their car in a box behind the camper and the Duramax. And my wife is cool with it! (I am so sick of the hassles of driving to the track)

And Doug, get a load of this.

Last year during the third week of March I fired up the system. Holy $hit! I runs good! The phone rings. It's a buddy who's keeping track of the system installation. I fill him in. He asks 'when is the next race?'. I check. FOUR HOURS! OMG! On go the race tires and the rest of my junk for the strip and off I go. Pay my money, pull to the line and go. BRAND NEW untested fuel system. Banged out an 11:89! First try. Fastest ever. Cold as hell, still winter. Then the computer started taking power out of it. Lost .2 on the next run. I could feel it take power when I hit second gear. The system was still a total mystery to me and I've not been able to match that run all last season. Weird huh? But that new roller cam is looking better every minute. But first on the list is my new air conditioned, enclosed (of course) car hauler. Real men come to the track with their car in a box behind the camper and the Duramax. And my wife is cool with it! (I am so sick of the hassles of driving to the track)

Dougs72Nova

Discussion starter

2,368 posts

·

Joined 2006

11.89. Very cool Fred! Are you going to a hydraulic roller or solid roller? By all means a roller camshaft is the way to make power. I wish i had one of those trailers you are talking about.:yes:Thanks for the options Jody and Doug.

And Doug, get a load of this.

Last year during the third week of March I fired up the system. Holy ! I runs good! The phone rings. It's a buddy who's keeping track of the system installation. I fill him in. He asks 'when is the next race?'. I check. FOUR HOURS! OMG! On go the race tires and the rest of my junk for the strip and off I go. Pay my money, pull to the line and go. BRAND NEW untested fuel system. Banged out an 11:89! First try. Fastest ever. Cold as hell, still winter. Then the computer started taking power out of it. Lost .2 on the next run. I could feel it take power when I hit second gear. The system was still a total mystery to me and I've not been able to match that run all last season. Weird huh? But that new roller cam is looking better every minute. But first on the list is my new air conditioned, enclosed (of course) car hauler. Real men come to the track with their car in a box behind the camper and the Duramax. And my wife is cool with it! (I am so sick of the hassles of driving to the track)

22,190 posts

·

Joined 1999

Very nice looking setup Doug, can't wait to here how she runs.

Any chance of putting up a pictoral on the install in EFI, for reference?

Some screen shots of the software running would be cool too.

Any chance of putting up a pictoral on the install in EFI, for reference?

Some screen shots of the software running would be cool too.

Dougs72Nova

Discussion starter

2,368 posts

·

Joined 2006

Thanks Jim.:thumbsup: I will shoot some pictures of the efi and fuel system install and start a thread over there when i get everything up and going.

6,628 posts

·

Joined 2008

Doug awesome and clean set up... Love the valve covers, i just got the same covers for my BB. Keep up the good work and pics.

Dougs72Nova

Discussion starter

2,368 posts

·

Joined 2006

Thanks Skip.:thumbsup: Here is a picture of the Glenn's performance fuel tank i bought. It has a baffled sump with two #8 an fittings and one #6 above for my return line.

Attachments

-

80.8 KB Views: 106

434 posts

·

Joined 2004

wow, now that is what i am talking about

that EFI is nearly undetectable!

absolutely gorgeous

that EFI is nearly undetectable!

absolutely gorgeous

Dougs72Nova

Discussion starter

2,368 posts

·

Joined 2006

Thanks.:thumbsup: It was not easy integrating a mass airflow unit inside the cowl air cleaner!

548 posts

·

Joined 2007

Looks great. Couple Questions:

Where'd you mount the computer?

Did you buy a new one from Chris or get a donor computer from another car to use?

Did you run the wires yet for the injector & MAF/TB? Where'd you run those to keep them out of sight?

What did you have to do to make the cowl air cleaner fit?

Tuning the carb in my car is getting a bit old. It's till not right and the gas fumes stink up the garage and even the inside of the car when I step on it.

I miss the clean running EFI I had in my last car.

Where'd you mount the computer?

Did you buy a new one from Chris or get a donor computer from another car to use?

Did you run the wires yet for the injector & MAF/TB? Where'd you run those to keep them out of sight?

What did you have to do to make the cowl air cleaner fit?

Tuning the carb in my car is getting a bit old. It's till not right and the gas fumes stink up the garage and even the inside of the car when I step on it.

I miss the clean running EFI I had in my last car.

Dougs72Nova

Discussion starter

2,368 posts

·

Joined 2006

Thanks Dan.:thumbsup:

Computer and harness are next on my list. I'll post some pictures when i start. I got the processor from Chris with the kit. It has a custom burned chip which converts the firing order and for the 30 lb injectors and maf. The fitment of the mass airflow unit inside the air cleaner was not easy. I had to think about that one. I'll post some pictures of that as well. The part i like about this system is that i can cruise my car around with my wife sitting in the passenger seat, not the laptop. Sure i may not be able to squeek that last 5 hp out of it, but i know what the system is and what is cappable of! I have built 10 sec Mustangs with a stock 9al computer before. Some may dissagree with the system, but i have worked with this system for many years. I thank you for informing me of Chris at Mass-Flo.

Sure i may not be able to squeek that last 5 hp out of it, but i know what the system is and what is cappable of! I have built 10 sec Mustangs with a stock 9al computer before. Some may dissagree with the system, but i have worked with this system for many years. I thank you for informing me of Chris at Mass-Flo.

Computer and harness are next on my list. I'll post some pictures when i start. I got the processor from Chris with the kit. It has a custom burned chip which converts the firing order and for the 30 lb injectors and maf. The fitment of the mass airflow unit inside the air cleaner was not easy. I had to think about that one. I'll post some pictures of that as well. The part i like about this system is that i can cruise my car around with my wife sitting in the passenger seat, not the laptop.

Dougs72Nova

Discussion starter

2,368 posts

·

Joined 2006

Well. I have the wire harness installed. Most of the fuel system plumbed. Getting close. Do you guys think i would be doing the fuel system half way if i utilized the factory steel 3/8 feed line for the return? Or should i just go ahead and use the braided hose i already have and run the return in braided as well? Thanks

3,677 posts

·

Joined 2001

I ran 3/8 steel supply and return...used say two-three feet of 6an to connect the steel to the tank and to the fuel rails.

Dougs72Nova

Discussion starter

2,368 posts

·

Joined 2006

Thanks Paul.

Thanks Fred. I am using 3/8 line for feed and return. I only wish i had that L88 of yours so i could use a 1/2 feed line.I used the original steel 3/8" line for the return. The supply is 15' of braded 1/2" now.

8,373 posts

·

Joined 2006

I used the original steel 3/8" line for the return. The supply is 15' of braded 1/2" now.

9 posts

·

Joined 2001

Doug,

Just found this post. Nice Job! I too just purchased a MassFlo EFI system from Chris for my 69 BB Camaro. Your fuel rails looked polished, did you polish them? My intake/throttle body and fuel rails are currently at the polisher. Hopefully I will be able to start the install soon once my wife lets me(we just had our 2nd child) I will most definetly keep an eye on this thread for installation ideas. I would appreciate any pictures/advice you would be willing to share. Thanks in advance and keep up the great work

I will most definetly keep an eye on this thread for installation ideas. I would appreciate any pictures/advice you would be willing to share. Thanks in advance and keep up the great work

Lonnie

Just found this post. Nice Job! I too just purchased a MassFlo EFI system from Chris for my 69 BB Camaro. Your fuel rails looked polished, did you polish them? My intake/throttle body and fuel rails are currently at the polisher. Hopefully I will be able to start the install soon once my wife lets me(we just had our 2nd child)

Lonnie

Dougs72Nova

Discussion starter

2,368 posts

·

Joined 2006

Thanks Lonnie.

Congrats on the new addition to the family! I polished the fuel rails. They polished up easily. Let me know if i can help in anyway with your install. Did you buy your fuel system from Chris? I did and it's pretty thorough. I ended up buying a fuel tank with a baffled sump so i had to buy some different fittings, but other than that the fuel system kit was complete. I can get the measurements of where to drill your wire harness hole in the firewall. There is only one place in the firewall that is large enough for the hole you have to drill. It took some time to find a place to drill it. The wire harness has great placement of the connectors accept for the coil and the maf tape outs. Tho will have to be shortened. The only other problem i have ran into is the air cleaner. With the maf sensor sitting right on top of the throttle body, you will have to be selective on the air cleaner unless you are willing to put some fabrication time into one like i did. The use of a drop base will leave you modifying it. PM me or ask any questions you want on this thread. I will be more than happy to help.

I polished the fuel rails. They polished up easily. Let me know if i can help in anyway with your install. Did you buy your fuel system from Chris? I did and it's pretty thorough. I ended up buying a fuel tank with a baffled sump so i had to buy some different fittings, but other than that the fuel system kit was complete. I can get the measurements of where to drill your wire harness hole in the firewall. There is only one place in the firewall that is large enough for the hole you have to drill. It took some time to find a place to drill it. The wire harness has great placement of the connectors accept for the coil and the maf tape outs. Tho will have to be shortened. The only other problem i have ran into is the air cleaner. With the maf sensor sitting right on top of the throttle body, you will have to be selective on the air cleaner unless you are willing to put some fabrication time into one like i did. The use of a drop base will leave you modifying it. PM me or ask any questions you want on this thread. I will be more than happy to help.

Doug

Congrats on the new addition to the family!

Doug

22,190 posts

·

Joined 1999

I also did mine in 3/8", stainless hardline to the tank and back. Used teflon braid for the last couple feet to the engine.

The teflon is nice, very thin compared to rubber braid, about half the OD. Impervious to gas, won't ever seep or smell. Only downside is the line is very stiff.

The teflon is nice, very thin compared to rubber braid, about half the OD. Impervious to gas, won't ever seep or smell. Only downside is the line is very stiff.

8,373 posts

·

Joined 2006

Yep, good stuff. I used it for the hi temp line on my boats refer/freezer/AC compressor. It's the big line on the left. The small hose on the right is the oil return.

Hey! Is this the first time a 27hp Yanmar diesel has been in the performance section?

![Image]()

Hey! Is this the first time a 27hp Yanmar diesel has been in the performance section?

3,677 posts

·

Joined 2001

He, He...I thought about qualifying my explanation, but you just came right out and busted me Jody!

What I was going to add is that...the idle PW is a set number in a preprogrammed ECU so you are stuck with whatever the programmer set it for.

For my setup...it is actually helpful as the injectors that I run are a little big so decreasing the fuel pressure at idle gets the PW where I want it to be and not so low that it becomes inconsistant.

What I was going to add is that...the idle PW is a set number in a preprogrammed ECU so you are stuck with whatever the programmer set it for.

For my setup...it is actually helpful as the injectors that I run are a little big so decreasing the fuel pressure at idle gets the PW where I want it to be and not so low that it becomes inconsistant.

14,879 posts

·

Joined 2000

yes, definitely an issue to remove the line if the tune is set for having the lower pressure at idle that the vacuum reference gives you. Then again, I wouldn't own an EFI system that I cannot tune, so it'd be a quick and simple adjustment to fix that area of the fuel map if I eliminated the reference line.

No problem Paul, everything you said is true. I was just stating that an EFI system can be set up either way with good results, as long as the tune is correct. There can be resolution issues at idle with a large injector, but I've run 95's without issue at idle, but some EFI boxes do a better job than others with large injectors.

Jody

No problem Paul, everything you said is true. I was just stating that an EFI system can be set up either way with good results, as long as the tune is correct. There can be resolution issues at idle with a large injector, but I've run 95's without issue at idle, but some EFI boxes do a better job than others with large injectors.

Jody

Dougs72Nova

Discussion starter

2,368 posts

·

Joined 2006

Update. Just about done. I wish i had more time to put into this thing. I made a panel to accept the ecm, fuse panel and check engine light. The panel fits where the glove box compartment is. The light is not in yet, but i figured i would show you guys the panel i made. I used riv nuts to install the ecm and fuse panel for easier removal if needed. It's mounted to the car at the normal lower three holes where the glove box door mounts and two to the cowl with riv nuts as well. The slot you see cutout at the bottom is where the fuse panel wire harness is going to be routed. I'm going to get a sheet of black felt and put it on the panel i made as well. The ecm sticker is upside down because the routing of my wire harness. I will probably just call Chris at Mass-Flo and have him send me another sticker to put on the ecm. What do you think? I think for doing this with basic tools at home it turned out pretty well. P.S.... All i have left is to wire the fuse panel and i will be ready to fire this baby up.:hurray:

P.S.... All i have left is to wire the fuse panel and i will be ready to fire this baby up.:hurray:

Attachments

-

84.2 KB Views: 105

-

90 KB Views: 106

548 posts

·

Joined 2007

Is the A9L the Ford mustang ECU? Does he reprogram that so it will have the right firing order or whatever else might be different on the chevy motor?

Dougs72Nova

Discussion starter

2,368 posts

·

Joined 2006

Hey Dan. Yes, the firing order, rev limiter, and injector pulse are all calibrated by Chris.

Dougs72Nova

Discussion starter

2,368 posts

·

Joined 2006

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

- posts

- 2.4M

- members

- 90K

- Since

- 1998

A forum community dedicated to 1st generation Chevy Camaros owners and enthusiasts. Come join the discussion about performance, builds, restoration, modifications, classifieds, troubleshooting, reviews, and more!

Explore Our Forums

Top Contributors this Month

View All

Sauron67MM

115 Replies

dhutton

109 Replies

FRANKTHECRANK

91 Replies