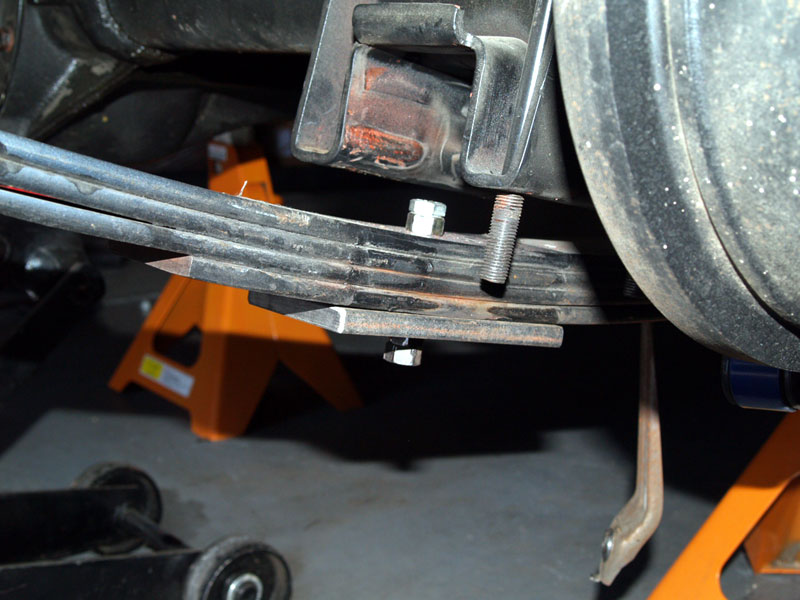

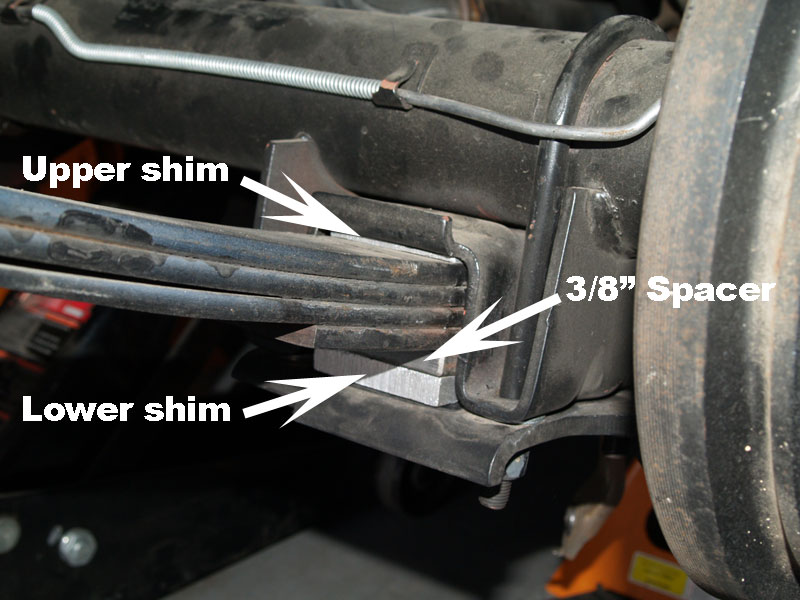

I think I need some leaf spring shims to raise the pinion 2* upward. currently the tranny sits 3.5 down pinion is .5-1* up and driveshaft is 2 degrees down.

That math makes me think i need a 2 degree ship upward on the leafsprings. I'm concerned if I put a shim in there the center bolt and the perch no longer will work as kind of a dowel so to speak. Is there a recommended shim or what is the wisdom on that one as far as worrying about losing my centering pin?

Thanks,

Rick

That math makes me think i need a 2 degree ship upward on the leafsprings. I'm concerned if I put a shim in there the center bolt and the perch no longer will work as kind of a dowel so to speak. Is there a recommended shim or what is the wisdom on that one as far as worrying about losing my centering pin?

Thanks,

Rick