I figured rather than clogging up the overall build thread for my '69 with all the LS swap stuff I'd start a new thread.

I picked up a 6.0l out of a 2002 Silverado 2500 with 130,000 miles for $2k. That sounds like a lot of mileage when you think about it in terms of the older Chevy engines, but these things have been know to go 250k without needing a rebuild. The plan is to get it cleaned up, do a cam swap, install all the required mounts/adapters, and get it set into place in a few weeks. The wiring, fuel system, cooling, etc., will wait until March when the next round of funds come in.

Here she is coming out of the truck bed a few weeks ago

![Image]()

I started disassembly with removal of the wiring harness

![Image]()

I then took the trans and converter off so I could get the engine on the stand

![Image]()

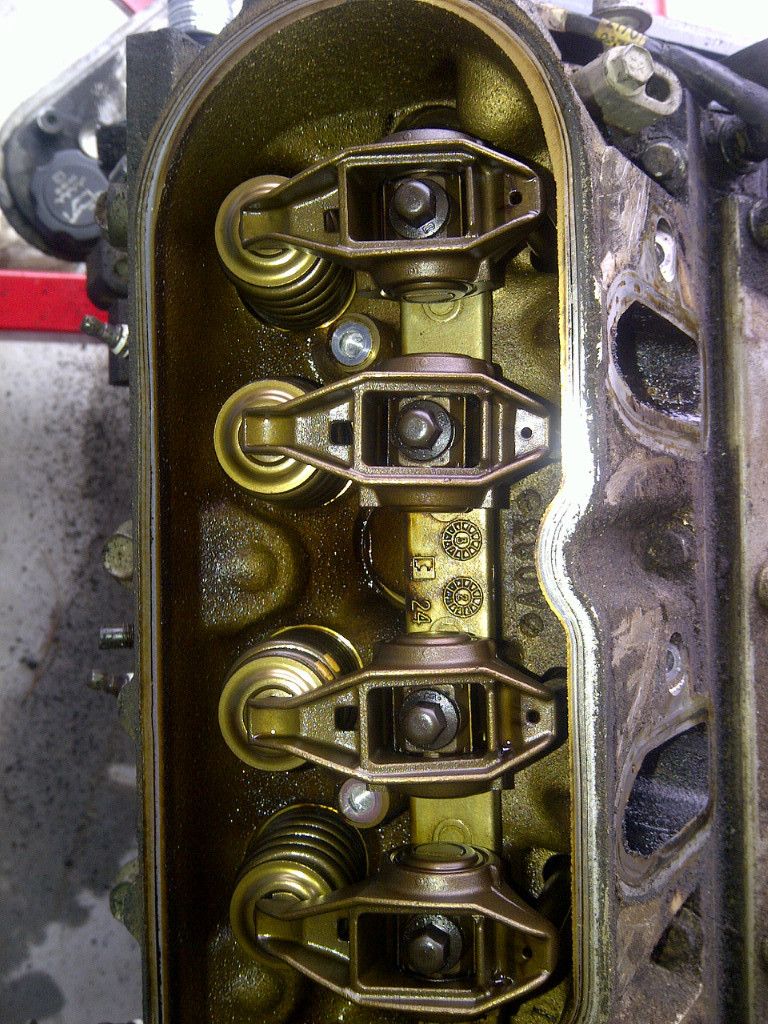

Both the cylinder heads and the bottom end are incredibly clean for an engine with 130k

![Image]()

![Image]()

Here's the LS1 intake that I picked up for $150, including the rails and injectors.

![Image]()

I got the block and heads cleaned up, and had three exhaust studs broken off flush with the heads that had to be removed by welding a washer and a bolt to them. Once that was fixed, I got the heads and block painted, and set the intake on.

![Image]()

I'm using Hooker engine mount adapters, which bolt to the 4-bolt arrangement on the block and have 3 holes to accept the standard old-style motor mount. I went with "stock location" plates, which will place the bellhousing right about where it normally was. They're also available in a few other configurations that slide the engine forward (to allow accessory clearance at the subframe), but that would cause interference between the oil pan and the center link.

![Image]()

The oil pan is Holley's Retro LS pan, which is a beautiful cast aluminum piece thats designed specifically to provide clearance at the center link. There are less expensive options out there, like the GM musclecar pan ($180 vs $400 for the Holley pan), but they're much deeper and hang a few inches below the subframe, which is a bad thing.

![Image]()

Here's a shot with the oil pan, intake and front cover temporarily in place. I've got a Z06 Corvette cam and valve springs coming this week that will go in over the weekend, and I'll post pics of that next week. I went with a semi-gloss black on the block, cast aluminum on the heads, and flat black on the valve covers just to break it up a bit.

![Image]()

I picked up a 6.0l out of a 2002 Silverado 2500 with 130,000 miles for $2k. That sounds like a lot of mileage when you think about it in terms of the older Chevy engines, but these things have been know to go 250k without needing a rebuild. The plan is to get it cleaned up, do a cam swap, install all the required mounts/adapters, and get it set into place in a few weeks. The wiring, fuel system, cooling, etc., will wait until March when the next round of funds come in.

Here she is coming out of the truck bed a few weeks ago

I started disassembly with removal of the wiring harness

I then took the trans and converter off so I could get the engine on the stand

Both the cylinder heads and the bottom end are incredibly clean for an engine with 130k

Here's the LS1 intake that I picked up for $150, including the rails and injectors.

I got the block and heads cleaned up, and had three exhaust studs broken off flush with the heads that had to be removed by welding a washer and a bolt to them. Once that was fixed, I got the heads and block painted, and set the intake on.

I'm using Hooker engine mount adapters, which bolt to the 4-bolt arrangement on the block and have 3 holes to accept the standard old-style motor mount. I went with "stock location" plates, which will place the bellhousing right about where it normally was. They're also available in a few other configurations that slide the engine forward (to allow accessory clearance at the subframe), but that would cause interference between the oil pan and the center link.

The oil pan is Holley's Retro LS pan, which is a beautiful cast aluminum piece thats designed specifically to provide clearance at the center link. There are less expensive options out there, like the GM musclecar pan ($180 vs $400 for the Holley pan), but they're much deeper and hang a few inches below the subframe, which is a bad thing.

Here's a shot with the oil pan, intake and front cover temporarily in place. I've got a Z06 Corvette cam and valve springs coming this week that will go in over the weekend, and I'll post pics of that next week. I went with a semi-gloss black on the block, cast aluminum on the heads, and flat black on the valve covers just to break it up a bit.